Understanding Busbar Insulators: Critical Components in Electrical Systems

The importance of busbar insulators in the field of electrical engineering cannot be underestimated. These components play a vital role in ensuring the safe and efficient operation of electrical systems, particularly in substations, switchgear, and various industrial applications. This article delves into the meaning, types, and applications of busbar insulators, shedding light on their critical role in modern power infrastructure.

What are busbar insulators?

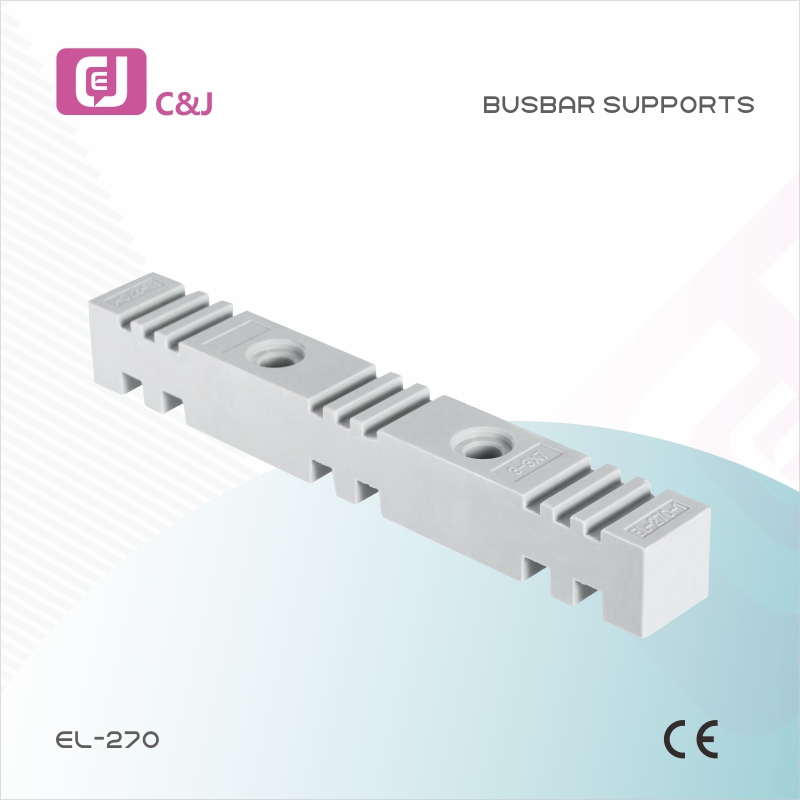

Busbar insulators are devices used to support and electrically isolate busbars, the conductive material that distributes electrical current in power systems. Busbars, typically made of copper or aluminum, connect multiple circuits, enabling efficient power transmission. However, to prevent short circuits and ensure safety, busbars must be properly insulated. This is where busbar insulators come in handy.

Types of busbar insulators

There are many different types of busbar insulators, each designed to meet specific operating requirements. The most common types include:

1. Porcelain Insulator: Porcelain insulators are widely used in outdoor applications, known for their durability and resistance to environmental factors. They can withstand high voltages and are less susceptible to degradation over time.

2. Polymer insulators: These are made of composite materials and are lighter than porcelain insulators. They offer excellent resistance to pollution and are often used in urban areas where air quality may affect performance.

3. Glass insulators: Glass insulators have high mechanical strength and are resistant to UV radiation. Due to their high transparency and ease of inspection, they are often used in applications where visibility is critical.

4. Silicone rubber insulators: These insulators are becoming increasingly popular due to their flexibility and resistance to extreme weather conditions. They are particularly effective in highly polluted environments.

Application of busbar insulators

Busbar insulators are used in a wide range of industries. Some of the most common applications include:

- Power Generation: In power plants, busbar insulators are critical for connecting generators, transformers, and other equipment, ensuring safe and efficient energy distribution.

- Substation: Busbar insulators are critical components in substations. They help manage the flow of electricity from high-voltage transmission lines to the low-voltage distribution network.

- Industrial Facilities: Many manufacturing plants and industrial facilities rely on busbar insulators to maintain the integrity of their electrical systems, ensuring machines operate safely and efficiently.

- Renewable Energy: With the rise of renewable energy sources such as solar and wind power, busbar insulators are increasingly used in these systems to facilitate the integration of clean energy into the power grid.

The Importance of Proper Selection and Maintenance

Selecting the right type of busbar insulator is crucial to the lifespan and reliability of your electrical system. Factors such as rated voltage, environmental conditions, and mechanical stresses must be considered during the selection process. Regular maintenance and inspection of busbar insulators is also crucial to detect any signs of wear or damage that could lead to system failure or safety hazards.

In summary

Simply put, busbar insulators are indispensable components in the field of electrical engineering. Their ability to support and isolate busbars ensures the safe and efficient distribution of electricity across a wide range of applications. As technology continues to advance, the development of advanced materials and designs for busbar insulators will further enhance their performance and reliability, paving the way for a more sustainable and efficient energy future. Understanding the role and importance of busbar insulators is crucial for engineers and technicians in the field, as they contribute significantly to the safety and efficiency of power systems worldwide.

Post time: Aug-18-2025