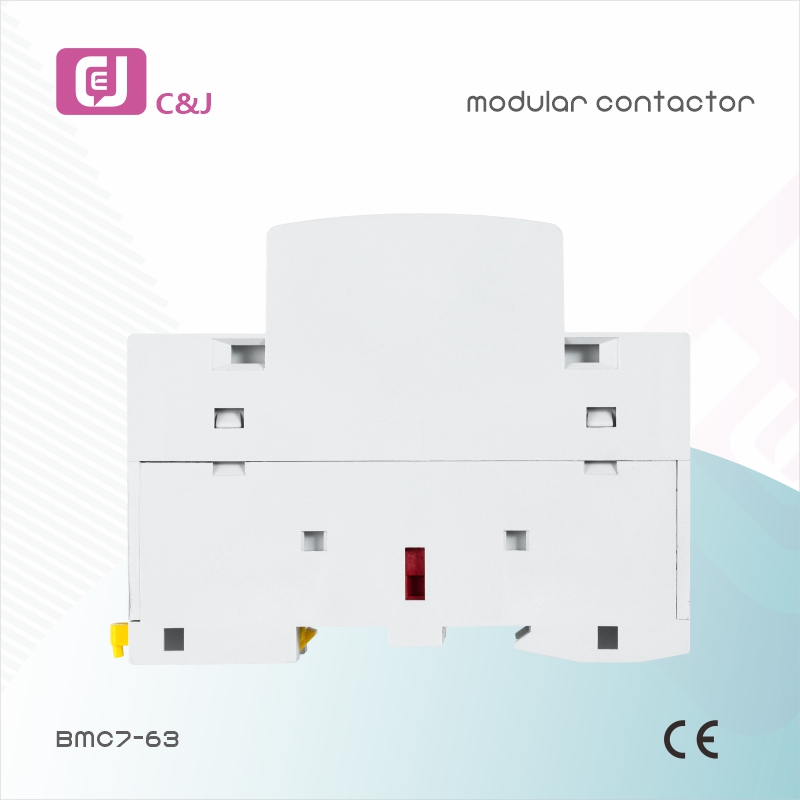

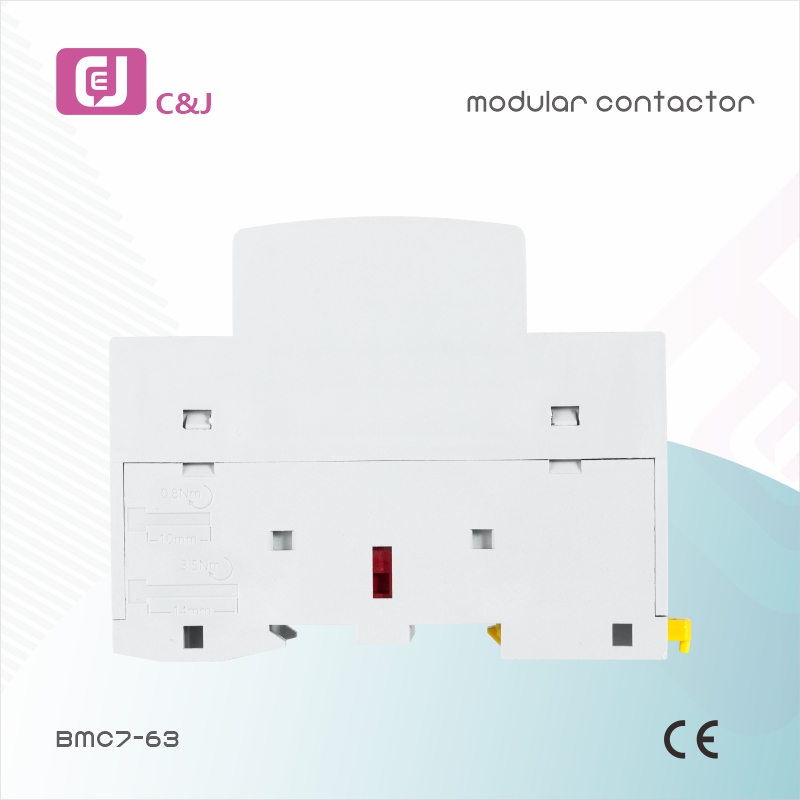

Understanding Modular Contactors: A Comprehensive Guide

The term “modular contactor” has gained a lot of attention in the world of electrical engineering and automation. These devices play a vital role in control circuits, especially in industrial and commercial applications. This article will take a deep dive into the intricacies of modular contactors, their functions, benefits, and applications.

What are modular contactors?

A modular contactor is an electromechanical switch used to control the current in a circuit. Unlike traditional contactors, modular contactors are compact and easy to integrate into modular systems. They are commonly used to switch electrical loads such as motors, lighting and heating systems. The modular design is easy to install, maintain and expand, making it an ideal choice for modern electrical systems.

How do modular contactors work?

Modular contactors work on the principle of electromagnetic induction. When current flows through the contactor coil, a magnetic field is generated that attracts a movable armature. This armature in turn closes or opens contacts, allowing or interrupting the flow of current. The modular design of these contactors means they can be stacked or combined with other modules, such as overload relays or timers, to create a customized control solution.

Advantages of modular contactors

1. Space saving: One of the most significant advantages of modular contactors is their compact design. Compared with traditional contactors, they take up less space and are ideal for applications with limited space.

2. Easy to install: Modular contactors are designed for quick and straightforward installation. Their plug-and-play nature enables them to be easily integrated into existing systems, reducing downtime during upgrades or maintenance.

3. Scalability: As industrial needs evolve, the requirements for electrical control systems also change. Modular contactors can be easily expanded or modified by adding or removing modules, providing flexibility for future development.

4. Enhanced safety: Many modular contactors are equipped with built-in safety features, such as overload protection and short-circuit protection. This ensures safe operation of the electrical system and reduces the risk of equipment damage.

5. Cost-effective: While the initial investment of modular contactors may be higher than traditional options, their long-term benefits (such as reduced maintenance costs and improved energy efficiency) often result in significant savings over time.

Application of modular contactors

Modular contactors are a versatile device used across a wide range of industries. Some common applications include:

- Motor Control: They are widely used to control electric motors in manufacturing plants, HVAC systems, and conveyor belts.

- Lighting Control: Modular contactors can manage the lighting systems of commercial buildings, achieving automatic control and energy saving.

- Heating Systems: Modular contactors can effectively control electric heaters and boilers in residential and industrial heating applications.

- Renewable Energy Systems: With the rise of solar and wind power, modular contactors are increasingly used in renewable energy systems to manage power distribution and ensure system reliability.

In short

All in all, modular contactors represent a significant advancement in electrical control technology. Their compact design, ease of installation, scalability, and safety make them ideal for a wide range of applications. As the industry continues to evolve and the demand for more efficient and flexible electrical solutions grows, modular contactors will undoubtedly play a key role in shaping the future of electrical engineering. Whether you are upgrading an existing system or designing a new one, considering modular contactors can improve the performance and reliability of electrical operations.

Post time: Jul-01-2025