Understanding Ac Mccb Types and Their Importance in Electrical Systems

Table of Contents

- AC MCCB Types Overview: Differentiating Between Standard and Specialized Models

- Key Specifications to Consider When Selecting AC MCCBs for Your Projects

- Importance of Breaking Capacity in AC MCCB: Ensuring Safety and Reliability

- How AC MCCBs Enhance Energy Efficiency in Modern Electrical Systems

- Application Areas: Where AC MCCBs Are Most Widely Utilized in Industry

- Regulatory Standards and Compliance for AC MCCBs in Electrical Installations

- Navigating the Future of Electrical Safety: Insights from Industry Reports on Factory Direct Sale of CJMM3-125L/3300 Air Switch MCCB Solutions

- FAQS

- Conclusion

- Related Posts

When it comes to electrical systems, understanding the different types of AC MCCBs (Air Circuit Molded Case Breakers) is pretty important—like, you really can’t overlook their role. As industries gear up with more advanced electrical setups, having reliable protection against overloads and short circuits has become a total must-have. Even the seasoned expert, Dr. John Smith, who’s been around the block in electrical engineering, points this out. He says, “Picking the right AC MCCB is absolutely crucial for keeping things both safe and efficient.”

These MCCBs are basically the essential link between smooth operation and avoiding potential risks. That’s why it’s so important for engineers and electricians alike to really get what types exist and how they work. Whether you’re dealing with a home setup or managing big industrial systems, choosing the right MCCB can protect your equipment and keep everything running without a hitch. Knowing key details like current ratings, trip settings, and how they work with modern digital systems helps professionals make smarter choices—ultimately boosting safety and performance.

As electrical tech keeps changing and evolving, staying updated on new AC MCCB models and features is more important than ever. So, in this guide, we’ll explore the different types out there, what they’re used for, and why they’re such a cornerstone of a reliable electrical infrastructure.

AC MCCB Types Overview: Differentiating Between Standard and Specialized Models

When exploring the realm of AC MCCBs (Air Circuit Breakers), it is essential to recognize the different types available, particularly the distinction between standard and specialized models. Standard MCCBs are designed for general applications, offering basic circuit protection and overload capabilities suitable for most electrical systems. These models typically include adjustable trip settings, allowing for customization according to specific load requirements. Their robustness makes them a go-to choice for industrial and commercial environments, providing reliable performance in managing electrical distribution.

On the other hand, specialized MCCBs serve distinct purposes and are engineered for unique applications that demand enhanced functionality. These may include features such as higher interrupting capacities, advanced monitoring capabilities, or integration with control systems. For instance, specialized MCCBs can be tailored for use in renewable energy systems, data centers, or critical infrastructure, where the failure of a circuit could lead to significant operational disruptions. Understanding the nuances between these types is vital for selecting the right circuit breaker, ensuring not just compliance with safety regulations but also optimizing the efficiency and reliability of electrical systems.

Understanding AC MCCB Types and Their Importance in Electrical Systems

Key Specifications to Consider When Selecting AC MCCBs for Your Projects

When selecting AC Molded Case Circuit Breakers (MCCBs) for your projects, several key specifications must be taken into account to ensure optimal performance and safety. First and foremost, the current rating and breaking capacity of the MCCB are crucial. The current rating should match or exceed the maximum load current expected in the electrical system, while the breaking capacity must be sufficient to handle potential fault currents without failing. This ensures that the circuit breaker can effectively interrupt excessive currents during short circuit conditions, protecting both the electrical equipment and personnel.

Another important consideration is the number of poles required for the application, which depends on the specific configuration of the electrical system. Common configurations include single, two, or three-pole options, with the supply voltage dictating the choice. Additionally, features such as thermal and magnetic trip settings are essential for customizing the MCCB's response to overloads and short circuits. Adjustable trip settings can provide flexibility and precision, allowing engineers to tailor the MCCB's operation to the specific characteristics of the load it serves.

Lastly, additional functionalities like built-in shunt trips, under-voltage releases, and auxiliary contacts can enhance the MCCB's functionality and integration into broader electrical control systems. These features enable improved automation, reliability, and safety measures in modern electrical installations. Thus, a well-informed selection of AC MCCBs, focusing on these specifications, can greatly contribute to the overall efficiency and safety of electrical projects.

Understanding AC MCCB Types and Their Importance in Electrical Systems - Key Specifications to Consider When Selecting AC MCCBs for Your Projects

| Specification | Description | Importance |

|---|---|---|

| Rated Current (In) | The maximum continuous current that the MCCB can carry. | Essential for selecting an MCCB suitable for the load it will protect. |

| Breaking Capacity (Icu) | The maximum fault current that the MCCB can safely interrupt. | Crucial for ensuring system safety under fault conditions. |

| Voltage Rating (Un) | The nominal voltage for which the MCCB is designed to operate. | Important for matching the MCCB with the system voltage. |

| Number of Poles | The number of electrical paths the MCCB can control. | Necessary to determine if it fits the configuration of your circuit. |

| Tripping Type | The type of mechanism used for tripping (thermal, magnetic, or electronic). | Impacts the sensitivity and speed of response to faults. |

| Environmental Protection Rating | Indicates the level of protection against dust and moisture. | Essential for operation in harsh environments. |

Importance of Breaking Capacity in AC MCCB: Ensuring Safety and Reliability

In the realm of electrical systems, the significance of breaking capacity in AC molded case circuit breakers (MCCBs) cannot be overstated. Breaking capacity, defined as the maximum fault current that a circuit breaker can safely interrupt without causing damage, is a critical parameter that directly influences the safety and reliability of electrical installations. According to a report by the International Electrotechnical Commission (IEC), the breaking capacity of MCCBs typically ranges from 6kA to 100kA, with higher ratings being essential for industrial and commercial applications where fault currents can be exceedingly high.

Understanding the importance of adequate breaking capacity is crucial for preventing catastrophic failures in electrical systems. Inadequate breaking capacity can lead to circuit breaker failure during an overcurrent situation, resulting in equipment damage, electrical fires, and even jeopardizing personnel safety. For instance, an analysis by the National Fire Protection Association (NFPA) indicates that electrical failures are responsible for approximately 25% of industrial fires in the United States, highlighting the need for superior breaking capacity in MCCBs to mitigate such risks. Proper selection of MCCBs with appropriate breaking capacity ensures the integrity of power distribution systems while offering peace of mind that operations will continue smoothly, even under fault conditions.

How AC MCCBs Enhance Energy Efficiency in Modern Electrical Systems

Modern electrical systems are driven by the urgent need for energy efficiency, particularly as industries strive to reduce operational costs and environmental footprints. Air Circuit Breakers, or MCCBs, are pivotal in achieving these goals. According to a report by the International Energy Agency (IEA), upgrading to advanced MCCBs can enhance energy savings by up to 15% in commercial applications. This is largely due to their ability to prevent overloads and short circuits, reducing energy waste and enhancing the overall reliability of power distribution.

In addition to their protective features, AC MCCBs boast advanced functionalities, such as adjustable trip settings and integrated monitoring systems. These capabilities not only optimize power delivery but also facilitate real-time energy management. By analyzing data trends, industries can make informed decisions regarding their energy use, leading to further efficiencies. The U.S. Department of Energy notes that the adoption of smarter circuit breakers has the potential to contribute to a 30% improvement in energy efficiency in new electrical installations.

**Tips:** When selecting MCCBs, consider those that offer energy monitoring and data analytics features. Additionally, performing regular maintenance checks can ensure their optimal performance and longevity, contributing to sustained energy efficiency throughout the lifespan of the electrical system.

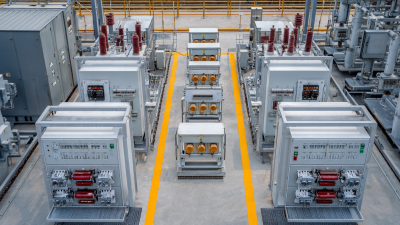

Application Areas: Where AC MCCBs Are Most Widely Utilized in Industry

AC Molded Case Circuit Breakers (MCCBs) play a crucial role in various industrial applications due to their ability to manage electrical currents effectively while providing overload and short-circuit protection. In industrial settings, such as manufacturing, energy production, and chemical processing, MCCBs are essential for safeguarding equipment and ensuring operational efficiency. According to a report by Markets and Markets, the global market for MCCBs is expected to reach USD 6.02 billion by 2025, driven by the rising demand for reliable electrical protection solutions across these sectors.

One of the prominent application areas for AC MCCBs is in electrical distribution systems, where they help in managing electrical loads safely. Industries like oil and gas, mining, and pharmaceuticals often rely on MCCBs to protect their operations from unpredictable electrical faults. For instance, in the oil and gas sector, maintaining operational integrity is vital due to the potentially hazardous environments. The use of MCCBs enhances safety by preventing equipment damage and ensuring compliance with strict regulatory standards.

Furthermore, the increased adoption of automation in industries is further propelling the demand for these protective devices, as consistent and reliable electrical systems are paramount for automated processes to function optimally.

Regulatory Standards and Compliance for AC MCCBs in Electrical Installations

The regulatory standards and compliance requirements for AC MCCBs (Air Circuit Breakers) in electrical installations play a crucial role in ensuring the safety and reliability of electrical systems. In many regions, adherence to standards set by organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) is mandatory. For instance, IEC 60947-2 outlines the specific performance criteria and testing methods that MCCBs must meet to ensure their effectiveness in protecting electrical circuits from overloads and short circuits. Compliance with these standards not only enhances safety but also minimizes the risk of equipment damage and electrical hazards.

Moreover, recent industry reports indicate that the global market for AC MCCBs is projected to witness significant growth, driven by the increasing focus on energy efficiency and safety in electrical installations. According to a report by MarketsandMarkets, the market size for circuit breakers is anticipated to reach USD 10.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.5%. This growth underscores the importance of compliance with regulatory standards, as clients and industries increasingly prioritize equipment that meets rigorous safety specifications.

Companies that fail to adhere to these standards risk not only financial penalties but also the potential loss of market access and damage to their reputation. As the electrical landscape continues to evolve, maintaining compliance with established regulatory frameworks will be essential for the sustainable development of electrical systems worldwide.

Navigating the Future of Electrical Safety: Insights from Industry Reports on Factory Direct Sale of CJMM3-125L/3300 Air Switch MCCB Solutions

The CJMM3 series Moulded Case Circuit Breakers (MCCBs) play a crucial role in ensuring electrical safety across various applications. These devices are engineered to connect, carry, and interrupt current under both normal and specified abnormal conditions. Recent industry reports indicate that low-voltage power distribution systems are increasingly dependent on reliable circuit breaking solutions to enhance safety and operational efficiency. Specifically, in sectors such as electric power, construction, and industrial settings, the demand for robust MCCBs like the CJMM3-125L/3300 is surging, as they provide necessary overload and short circuit protection.

Moreover, the mechanical switch functionality of these MCCBs enables them to protect lines and equipment from potential hazards during operation, including undervoltage occurrences. Industry data suggests that the implementation of enhanced electrical safety measures, including modern MCCB solutions, has led to a significant reduction in electrical accidents in industrial environments, with some reports highlighting a decrease of up to 30% in incidents. This trend emphasizes the importance of adopting advanced circuit protection technologies. As the electrical landscape evolves, it is clear that investing in high-quality, reliable circuit breakers will be vital for ensuring both compliance and safety in electrical installations.

FAQS

C MCCBs?

Adequate breaking capacity is crucial for preventing catastrophic failures such as circuit breaker failure during overcurrent situations, which can lead to equipment damage, electrical fires, and personnel safety risks.

The breaking capacity of AC MCCBs typically ranges from 6kA to 100kA, with higher ratings being essential for industrial and commercial applications where fault currents can be exceedingly high.

AC MCCBs are widely utilized in industries such as manufacturing, energy production, chemical processing, oil and gas, mining, and pharmaceuticals.

MCCBs manage electrical loads effectively while providing overload and short-circuit protection, safeguarding equipment, and ensuring that operations run smoothly even during electrical faults.

Inadequate breaking capacities can lead to the failure of circuit breakers, resulting in equipment damage and increasing the risk of electrical fires.

The global market for MCCBs is anticipated to grow significantly, reaching USD 6.02 billion by 2025, driven by the increasing demand for reliable electrical protection solutions across various sectors.

In electrical distribution systems, MCCBs are essential for managing electrical loads safely and preventing operational disruptions caused by unpredictable electrical faults.

Consistent and reliable electrical systems are paramount for automated processes to function optimally, thus enhancing the overall safety and efficiency of industrial operations.

MCCBs help maintain operational integrity in potentially hazardous environments, such as the oil and gas sector, by preventing equipment damage and ensuring compliance with strict regulatory standards.

Conclusion

The article "Understanding AC MCCB Types and Their Importance in Electrical Systems" provides a comprehensive overview of AC MCCBs (Molded Case Circuit Breakers), distinguishing between standard and specialized models. It outlines key specifications to consider when selecting AC MCCBs for various projects, emphasizing the critical role of breaking capacity in ensuring safety and reliability in electrical systems.

Furthermore, the importance of AC MCCBs in enhancing energy efficiency is explored, highlighting their widespread application across various industries. The article also addresses the necessary regulatory standards and compliance measures required for AC MCCBs in electrical installations, underscoring their significance in maintaining safe and effective electrical operations. Overall, AC MCCBs play a vital role in modern electrical infrastructure, ensuring both operational efficiency and adherence to safety regulations.

Related Posts

-

Exploring the Advantages of Choosing the Best MCB and MCCB for Global Suppliers

-

Understanding the Distinct Features and Applications of Best MCB RCCB Alternatives for Global Buyers

-

Future Innovations in MCB and MCCB Technologies for 2025 A Comprehensive Guide

-

The Ultimate Guide to Choosing the Best Circuit Breaker Enclosures for Your Global Projects

-

How to Choose the Best MCCB Breaker Based on Load Demand and Safety Ratings

-

Essential Checklist for Choosing the Right Auto Recloser RCCB: Key Industry Metrics to Consider